Pillar cranes

- for installation and operation of pumps, mixers and other devices,

- for lifting and moving loads in a small area,

- when performing inspections or replacing devices,

- Due to their low weight, they can be used as portable.

Reach: up to 1,2 m

Load capacity: from 150 to 800 kg

Height: 2,4 m

Weight: from 45 to 64 kg

Column cranes are used wherever it is necessary to lower and lift heavy equipment and loads, e.g. in sewage treatment plants, food processing, fish farming, agriculture or industry. The use of a crane eliminates the need to manually lift heavy assemblies during their assembly, operation or replacement, which facilitates work and reduces the risk of damage to the device.

When selecting a crane in terms of lifting capacity, you should take into account additional loads that may occur while working at the workstation. When lifting a load in real conditions, additional loads must be taken into account, including:

- increased resistance caused by the presence of sand or other impurities,

- swinging (including vertical) of the load when lifting or lowering,

- load inertia due to sudden stopping of the lowered load,

- deflection causing an increase in the radius of reach and the load on the crane structure,

- dynamic lifting – uneven force on the crank (jerking) to make it easier to lift a heavy load.

Non-standard versions – after agreeing with the client, we can make a crane with non-standard dimensions. The reach can be extended from 1.2 m to a maximum of 1.8 m, and the lifting height from 2.0 to a maximum of 2.5 m. Increasing the reach or lifting height should not be done simultaneously, i.e. we increase the reach or lifting height. Due to the possibility of the winch colliding with railings or other already installed elements, it may be necessary to increase the winch mounting height.

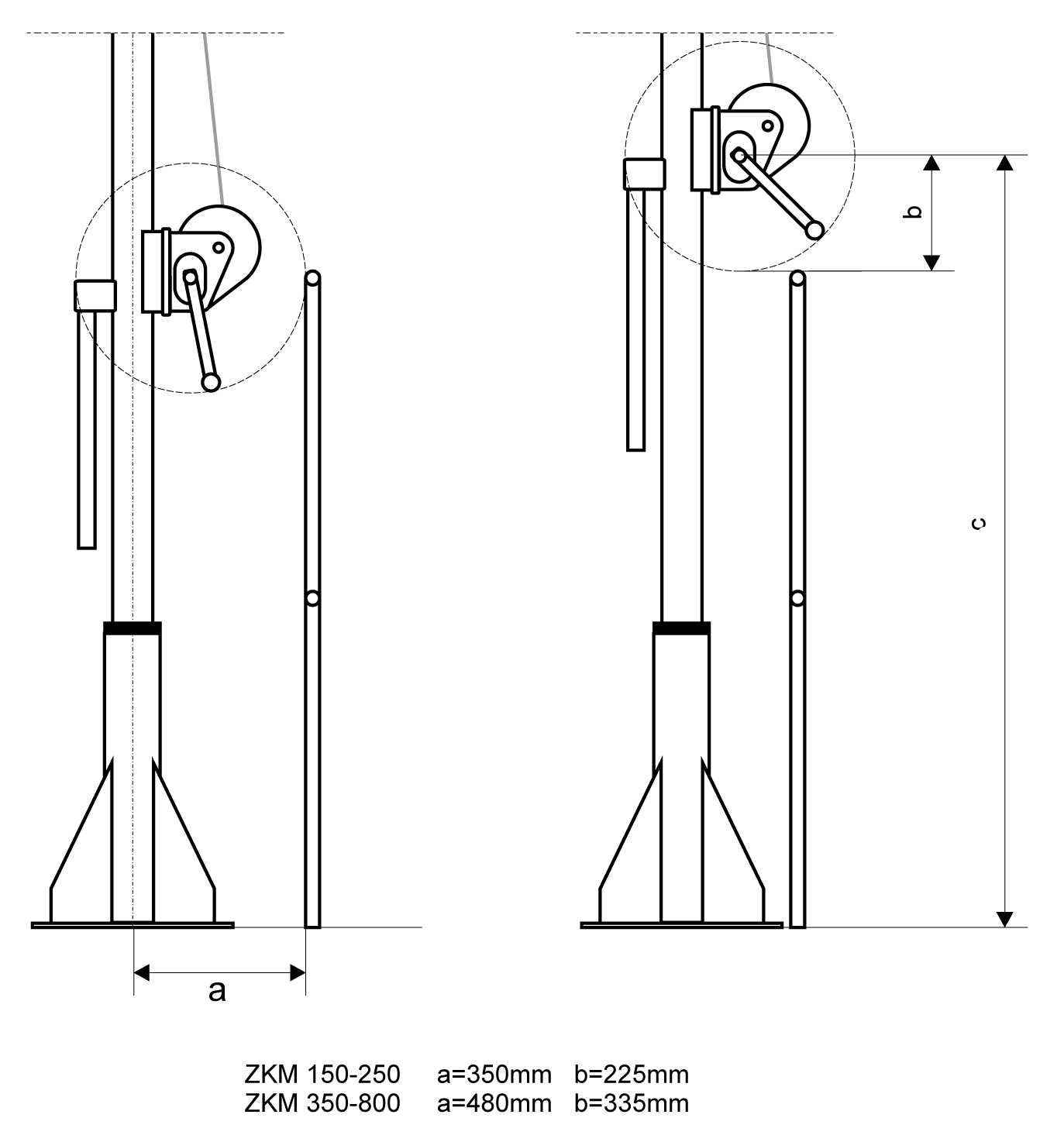

When designing the crane location, the limitations associated with the range of motion of the rope hoist crank shall be taken into account. The mounting height of the rope winch on the crane column can be adjusted to the customer‘s requirements. This is important in case of possible collisions with, for example, a barrier on the service platform.

If it is necessary to change the height of the winch mounting, the desired dimension “c” must be specified in the order, calculated from the ground level of the crane base to the axis of rotation of the winch crank.

Column cranes are manufactured in 2 material variants:

Made of galvanized steel – structural elements, screw elements, winch and foot are made of galvanized steel, rope, bail clamps, hook or shackle are made of stainless steel. When operating cranes in conditions that may cause accelerated corrosion of galvanized elements, it is recommended to use winches made of stainless steel.

Stainless steel – all structural, screw and connecting elements, including the foot and the winch, are made of 304/316 stainless steel. Cranes made entirely of stainless steel are used in particular when working in very chemically aggressive or humid environments, and wherever it is necessary to maintain high hygiene.

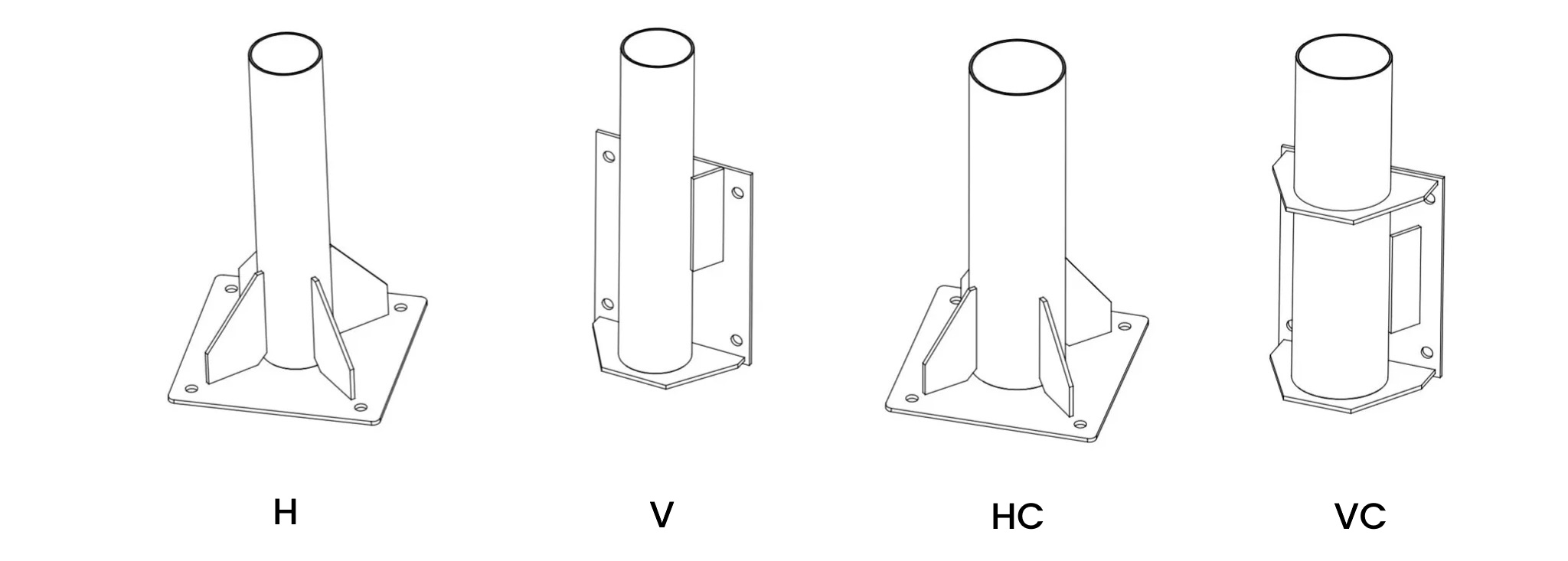

Crane foot – in order to enable the mounting of cranes in various terrain conditions, we offer two types of bases. H/HC type bases are designed to be mounted on a horizontal surface, V/VC type bases are attached to vertical walls. H or V type bases are used for ZKM150-350 cranes, while HC or VC type bases are used for ZKM500-800 cranes.

The base is attached to the ground using four screws or M16 chemical anchors with a strength class of min. 5.6 mounted in accordance with the manufacturer’s assembly instructions in a way that ensures transfer of their full strength. The use of identical screws to fasten the bases of all ZKM, ZKU and ZS cranes allows for their easy replacement later, e.g. if it is necessary to use a crane of a different type or with a higher capacity at the same workstation.

Chain hook – If the mixer or pump is suspended on a chain at the workstation to conveniently raise or lower the device with a crane, a chain hook can be installed at the end of the crane’s winch cable.

The self-hitch is designed for lifting and lowering pumps and mixers weighing up to 250-500 kG suspended on chains with a chain wire diameter of 4 to 10 mm made according to the DIN766 or DIN763 standard.

An essential condition for using the self-hitch is to be absolutely sure that it is correctly attached to the pump chain during lifting.

S8 – for chain link wire diameter from 4 to 6 mm and load capacity up to 250 kG

S10 – for chain link wire diameter from 6 to 8 mm and load capacity up to 350 kG

S12 – for chain link wire diameter from 8 to 10 mm and load capacity up to 500 kG