Aerating Mixers

- oxygenation and mixing of sewage in mechanical-biological sewage treatment plants,

- refreshing and pre-oxygenation in catchments and sewage pumping stations,

- supporting or replacing less effective devices such as: surface aerators, brushes, aeration grates and others.

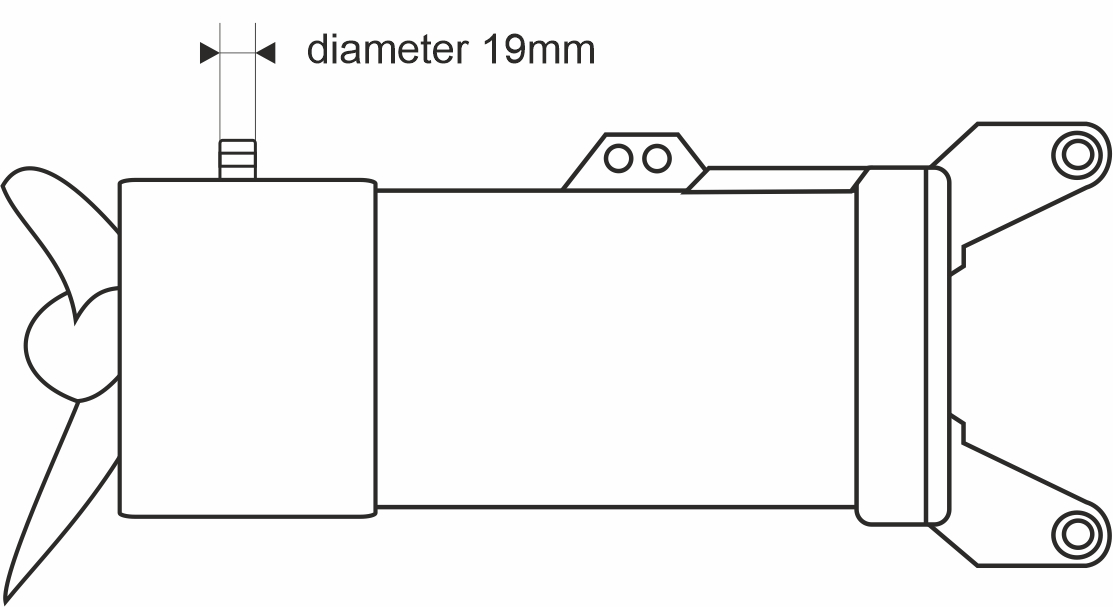

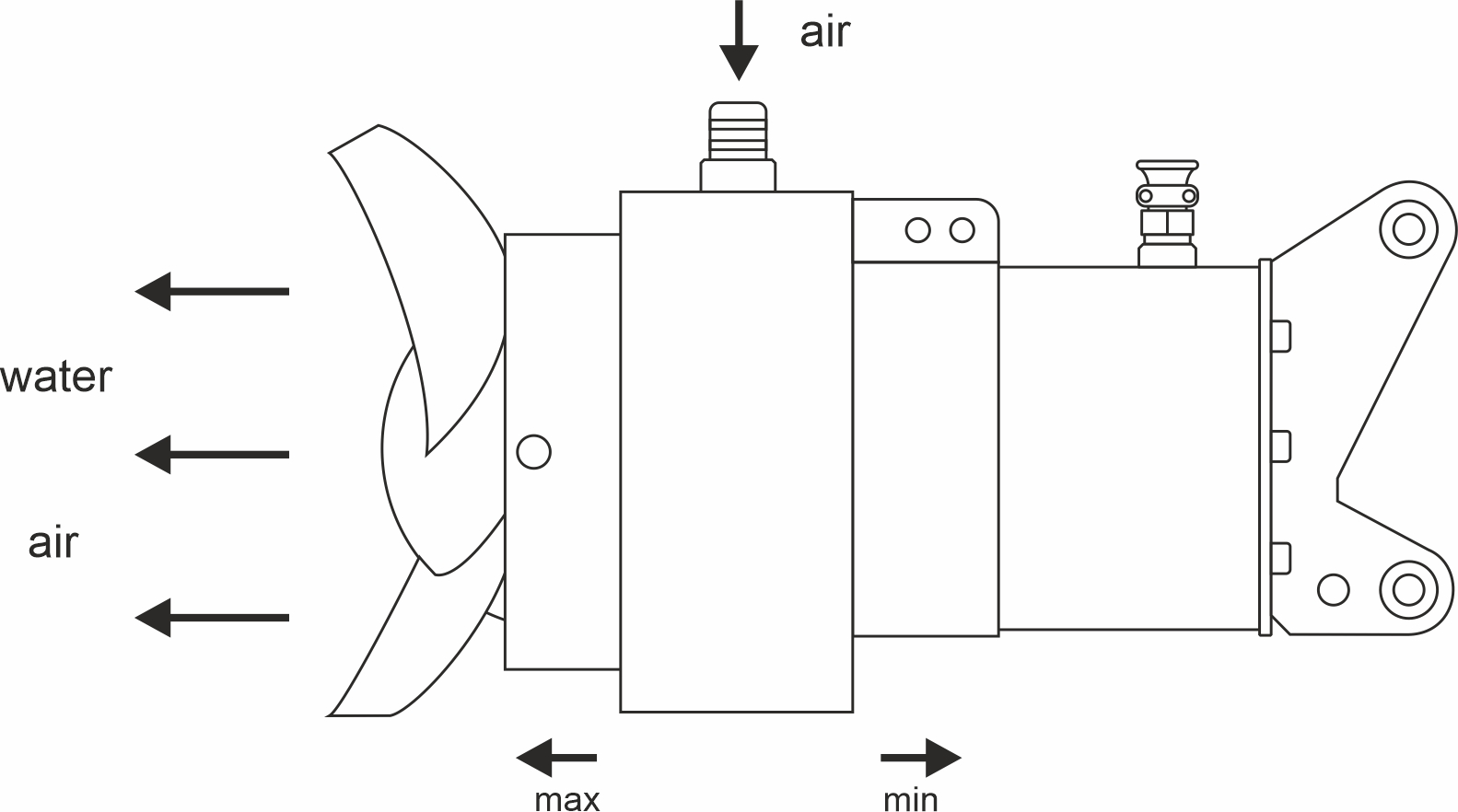

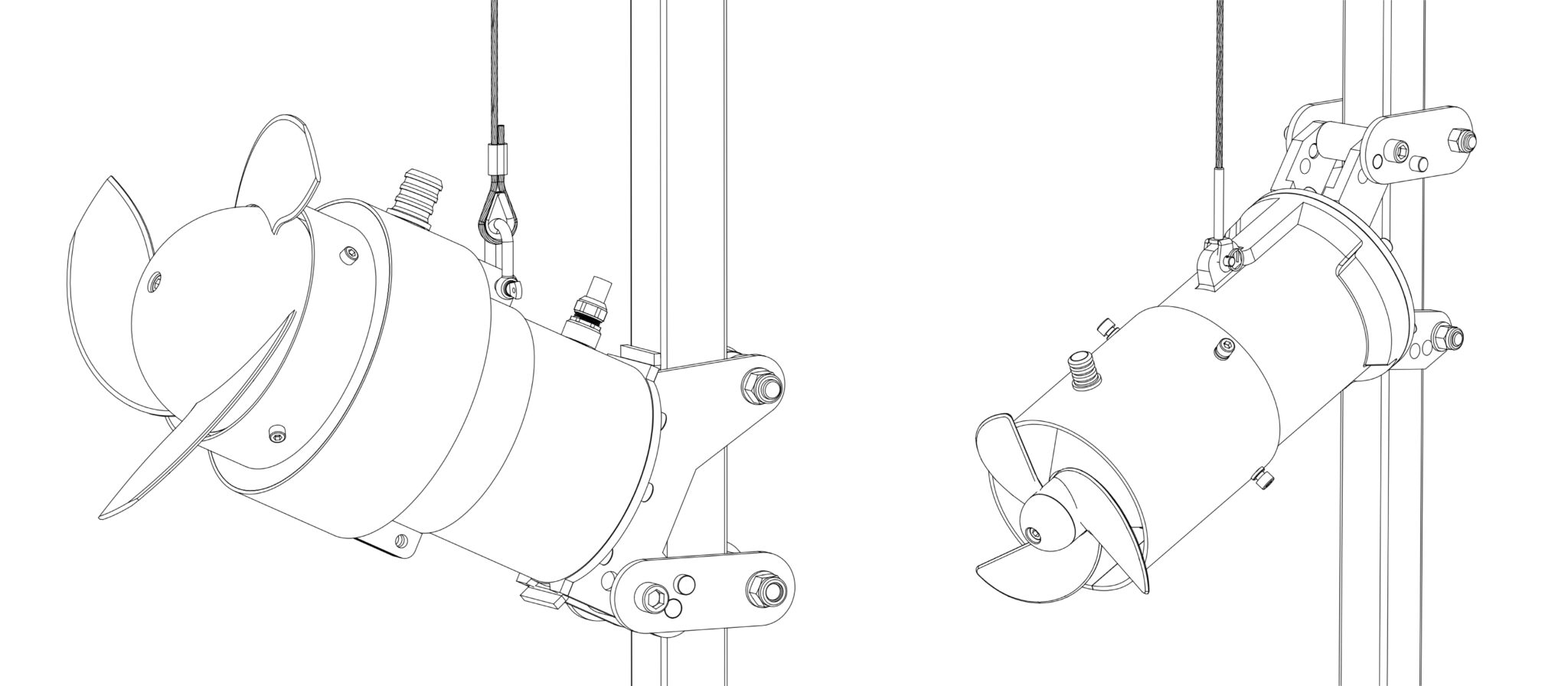

Submersible mixers can be equipped with an aeration cap thanks to which it is possible to mix sewage and aerate it at the same time. Oxygenation of wastewater, however, comes at the cost of deteriorating mixing efficiency. Mixers with an aeration attachment are used wherever there is a need for mixing with simultaneous aeration and it is not necessary to supply large amounts of air. Air is sucked in through a tube that is resistant to negative pressure at the working depth of the mixer. If an aeration attachment is used, a significant decrease in mixing capacity should be taken into account.

The operating parameters depend on the amount of air supplied to the mixer, but it should be taken into account that as oxygenation increases, the mixing capacity will decrease.

The attachment can be equipped with both Hydra and Turbo submersible mixers.

Control system – mixers can be equipped with a control cabinet, the basic variant of the cabinet includes protection against motor overload, phase loss, accidental change of phase sequence and the CR-3 signaling device. Of course, we can design and implement any control according to the customer’s guidelines; complex control systems are based on an inverter. The protection level of the cabinets – IP65 allows them to be used outdoors.

Electric motor protection:

– temperature control sensor – thermistors, built into the stator windings of the mixer motor, react when the safe operating temperature is exceeded. This protects the engine from damage due to overheating.

Temperature sensors should be used in engines subject to overheating. This applies to engines operating in places with elevated ambient temperatures (>40°), engines exposed to overloads, engines exposed to frequent or heavy starts, and engines in which cooling is weaker than standard.

For most submersible mixer motors there is no particular need for built-in thermal protection, assuming that the standard motor protection, in particular overload protection, is working properly. During operation, the mixers are intensively cooled by the liquid flowing around them and usually operate at temperatures much lower than permissible.

– water presence sensor in the oil chamber – A sensor with a probe in the oil chamber signals the presence of water in an amount greater than the permissible amount and the need to immediately change the oil combined with assessing the condition of the seals based on the analysis of the drained oil.

In most cases, mechanical face seals used in submersible mixers ensure complete tightness. However, seal manufacturers reserve the possibility of minimal leaks occurring in certain circumstances. Small amounts of water dissolve in the oil or create an emulsion that further works perfectly with seals. Larger amounts of water, which the oil is no longer able to absorb, accumulate in the lower part of the chamber and also do not affect the operation of the seals. Water from seal leaks is removed during periodic oil changes.

– moisture sensor in the engine compartment – During the final assembly of the mixer, an insert is placed inside the engine to absorb moisture from the air trapped in the engine compartment. This avoids moisture and condensation inside the engine.

The moisture sensor signals the presence of moisture inside the engine compartment caused by a leak. The activation of this sensor is an indication that the mixer should be immediately inspected to determine the cause of the leak.

– integrated CR-3 signaling device – Probes and security sensors built into the mixer can be operated by the integrated CR-3 signaling device designed especially for submersible mixers of our production. If any of the protections are activated, the mixer operation is stopped and the appropriate diode on the CR-3 sensor lights up, indicating the reason for stopping the mixer.

The CR-3 indicator is necessary for the correct operation of the sensors when the mixer is equipped with all 3 sensors (engine temperature, presence of water in the oil chamber, engine humidity).

Angle attachment – In the standard version, the mixer is mounted directly on the guide column in a horizontal position. In some cases, it is advisable to install the mixer inclined downwards, e.g. to better lift sediments or induce vertical circulation, or upwards to break up the foam that appears on the surface. The angle attachment, which is an additional accessory, allows you to tilt the mixer by an angle of 10 or 20 degrees up or down.

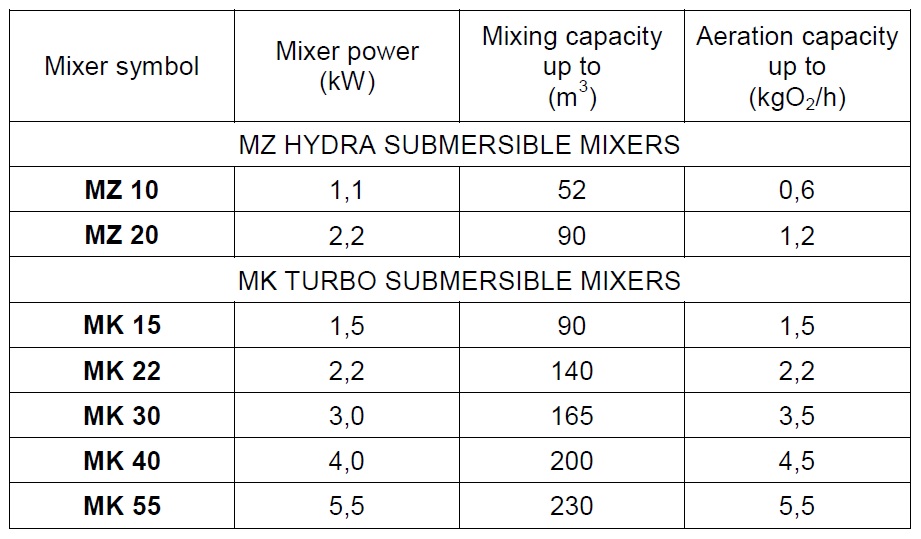

Power: 1,5 - 5,0 kW

Oxygenation capacity: up to 1,6 - 9,0 kg O2/h

Mixing capacity: up to 125 - 450 m3