Jet Aerators

- oxygenation and mixing of sewage in mechanical-biological sewage treatment plants,

- refreshing and pre-oxygenation in catchments and sewage pumping stations,

- supporting or replacing devices such as: surface aerators, brushes, aeration grates and others.

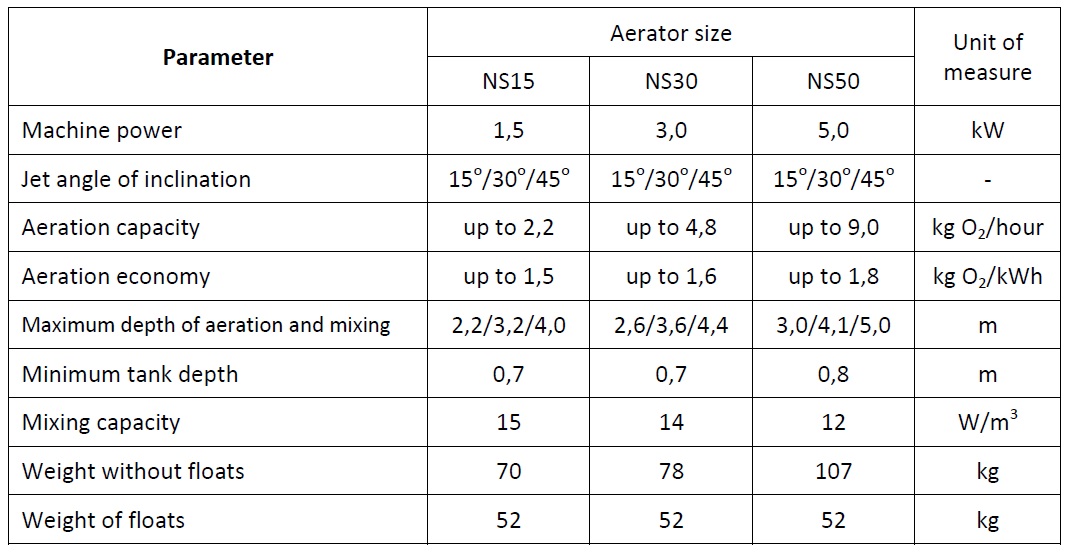

Power: 1,5 - 5,0 kW

Oxygenation capacity: do 1,5 - 9,0 kg O2/h

Max. oxygenation depth: 2,2 - 5,0 m

Mixing capacity: 12 - 15 W/m3

Weight of the device without floats: 70 - 107 kg

Jet oxygenators works based on the phenomenon of generating negative pressure and sucking in air through the liquid flowing through the nozzle – the so-called venturi nozzle. To power the jet, which is the most important part of the oxygenator, a multiple slot nozzle (so-called multiple slot nozzle) is used, which is characterized by a very high mixing capacity. The special shape of the nozzle does not allow it to be clogged, even by large solid particles.

The basic feature on which the design of oxygenators is based and which distinguishes them from other devices of this type is the principle of powering the jet by a propeller pump located above the sewage surface. In most cases, for effective oxygenation and mixing of sewage, it is not necessary to use jets powered by expensive and difficult to operate submersible pumps.

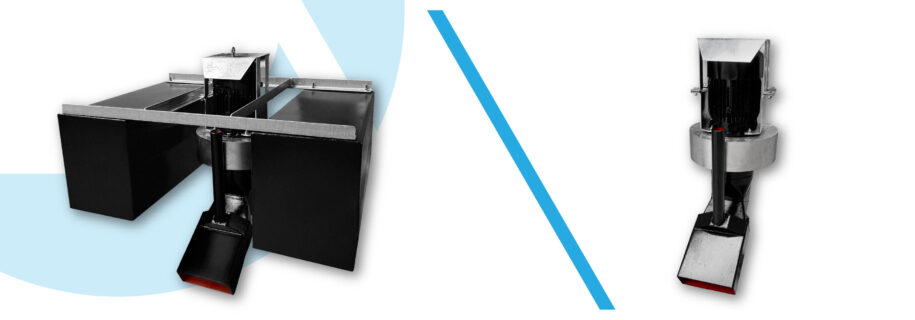

Jet oxygenators are produced in stationary and float versions:

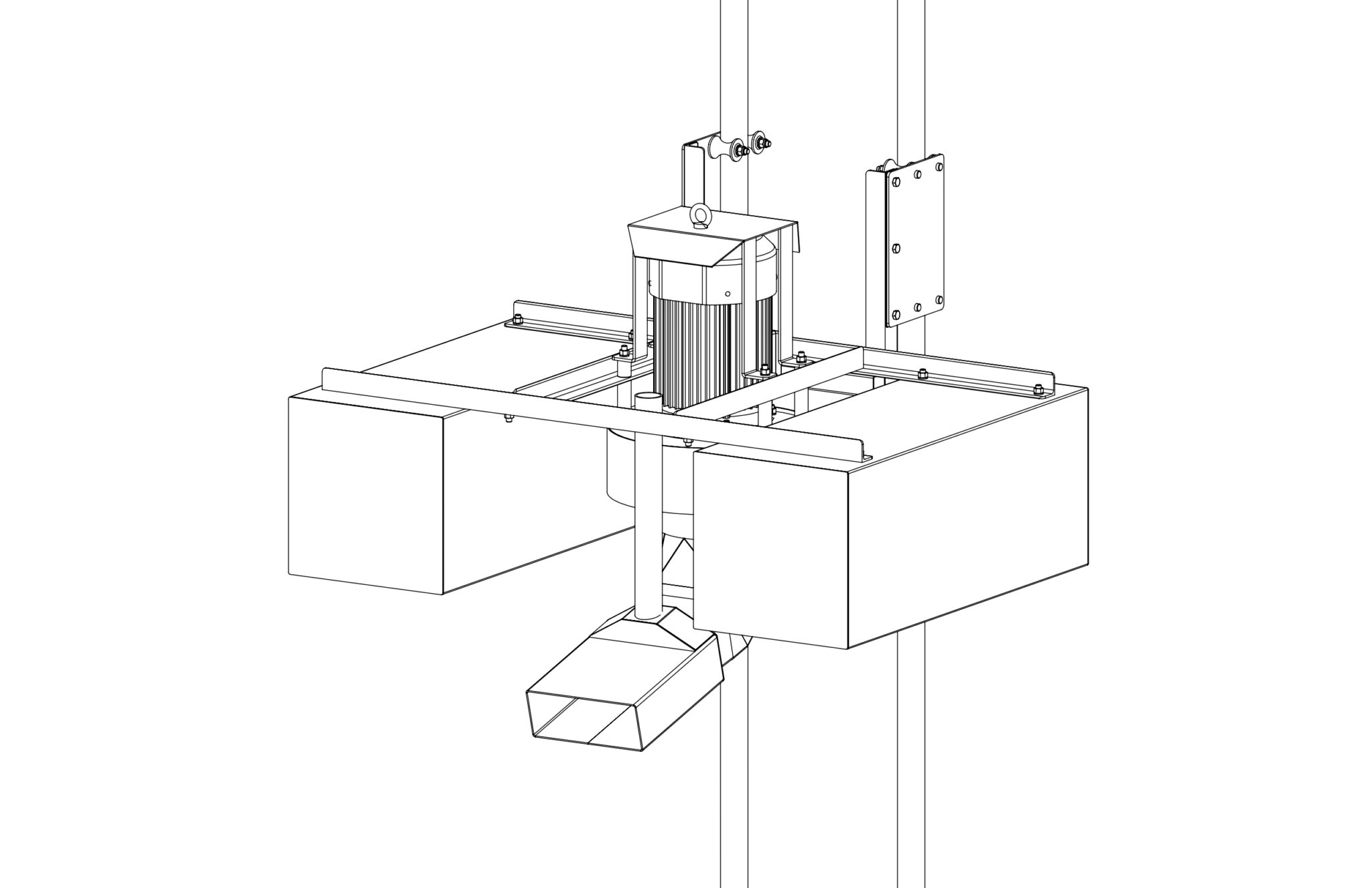

Float version – allows the oxygenator to operate at any fluctuations in the liquid level. The device in this version consists of a set of two floats to which an oxygenator is attached. The floating version is attached to the platform via roller guides or an articulated system that stabilizes the horizontal position of the floats.

Stationary version – used when it is necessary to oxygenate a tank with a constant liquid level or when attaching it to an existing floating structure. It has handles designed to be attached directly to the structure of the pier or quay. In cases where changes in the liquid level are greater or long-lasting, it is recommended to use the floating version of the device.

Jet oxygenators can be equipped with two stabilization systems:

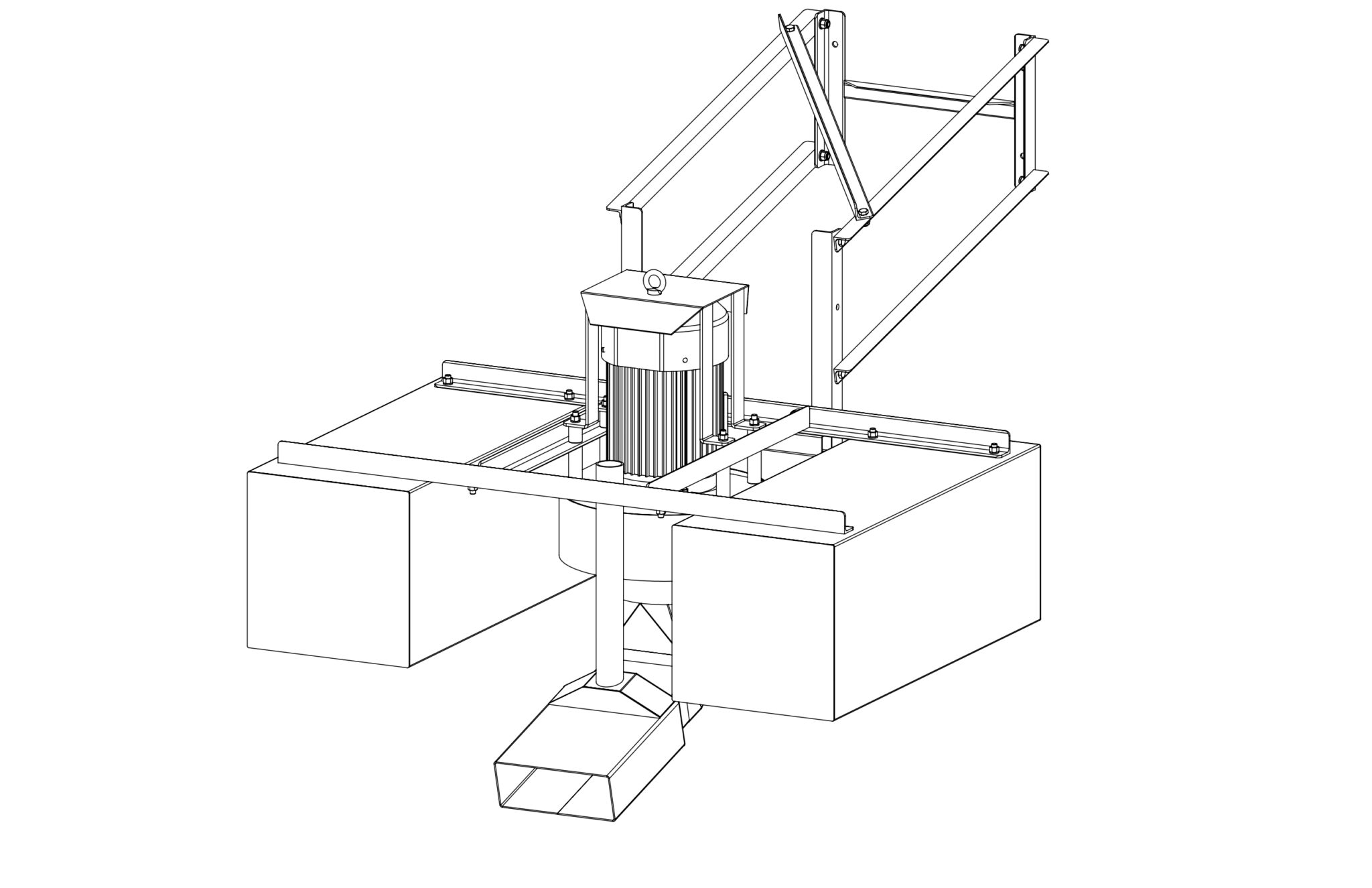

Articulated stabilizer – to maintain the horizontal position of the device, it should be equipped with a stabilization system. Due to the simplicity of installation, reliability of operation in winter conditions and very high flexibility in selecting the length of elements, it is a very good and universal solution. When using an articulated stabilizer, the device is not limited to working directly at the installation site.

Roller stabilizer – in cases where there are large fluctuations in the sewage level or the size of the tank is limited, roller guides can be used for stabilization. The rollers are mounted using the same holes in the angle brackets of the float connectors as in the case of mounting the joints.