Pneumatic decanter

- to drain the clarified surface layer of sewage.

Maximum performance: up to 300 m3/h

Drain pipe diameter: 60 - 160 mm

Stabilization system: articulated or roller

Number of floats: 2 or 4

DP pneumatic decanters allow periodic or continuous discharge of the clarified surface layer of sewage in small and medium-sized treatment plants operating in a sequential or continuous system. Decanters with pneumatic control enable the drainage trough to be raised above the sewage surface, which interrupts the sewage discharge. Raising the trough during breaks in sewage collection prevents contamination of the discharged, clarified sewage with activated sludge. We offer two variants of decanters: two-float and four-float.

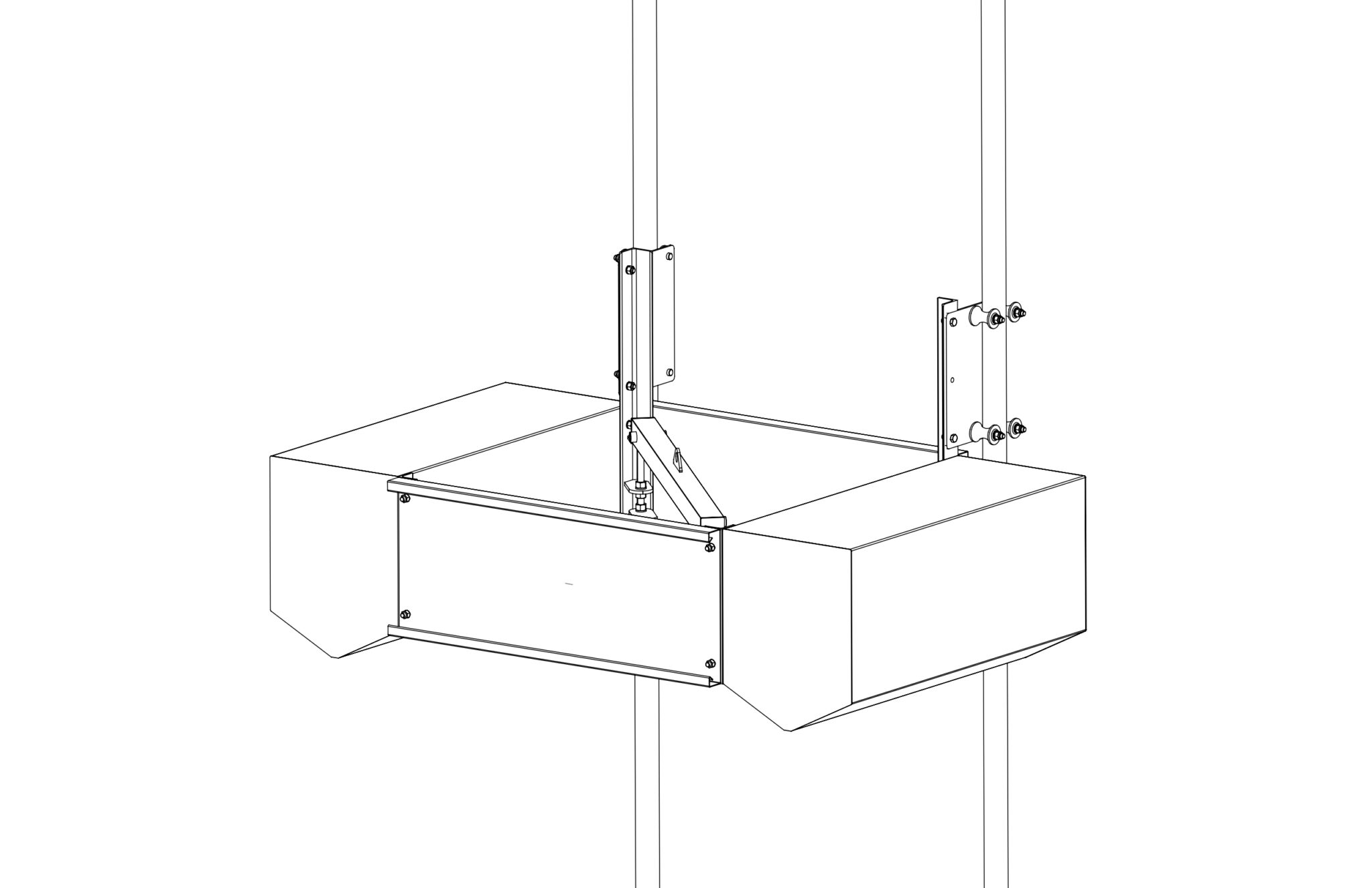

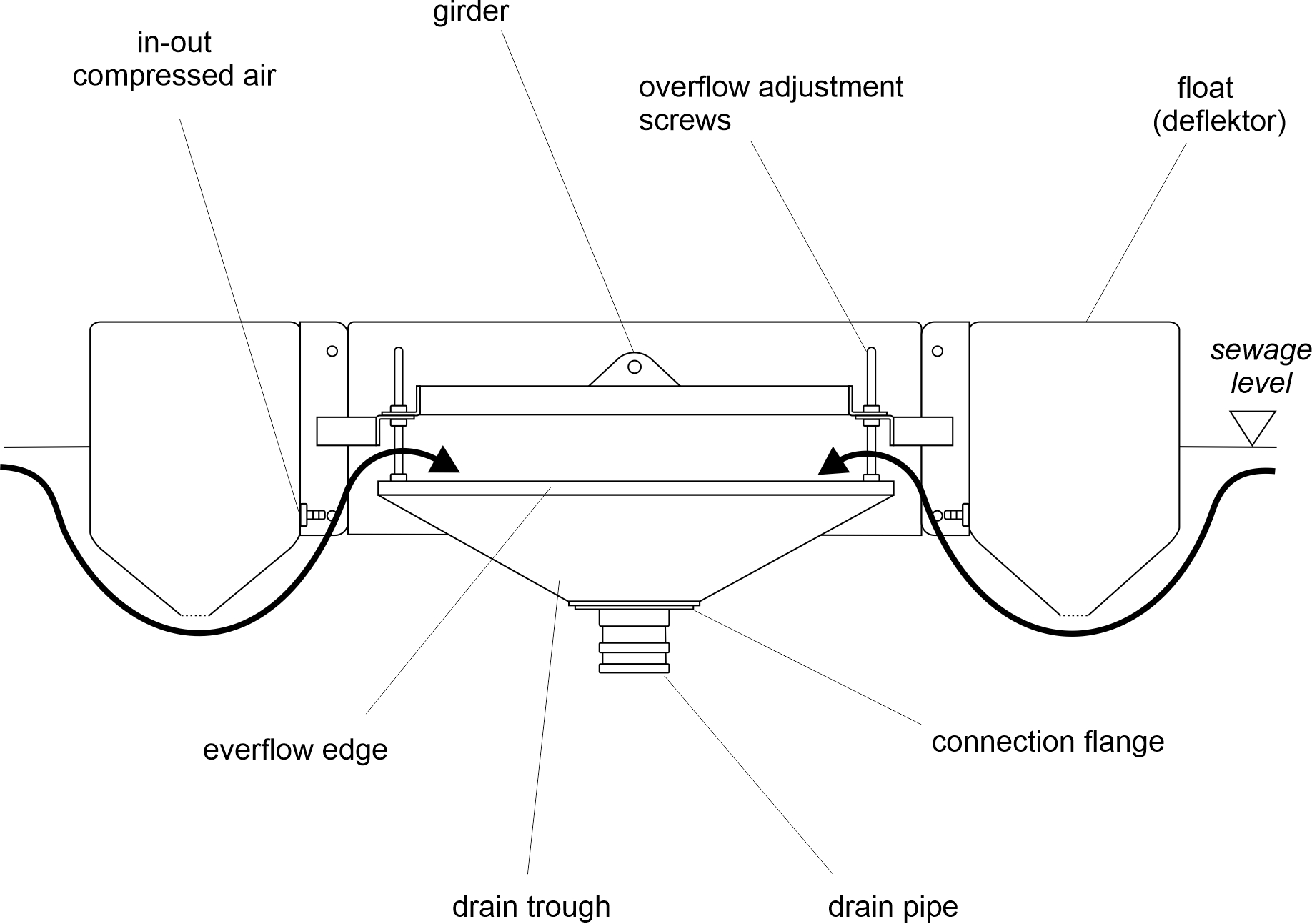

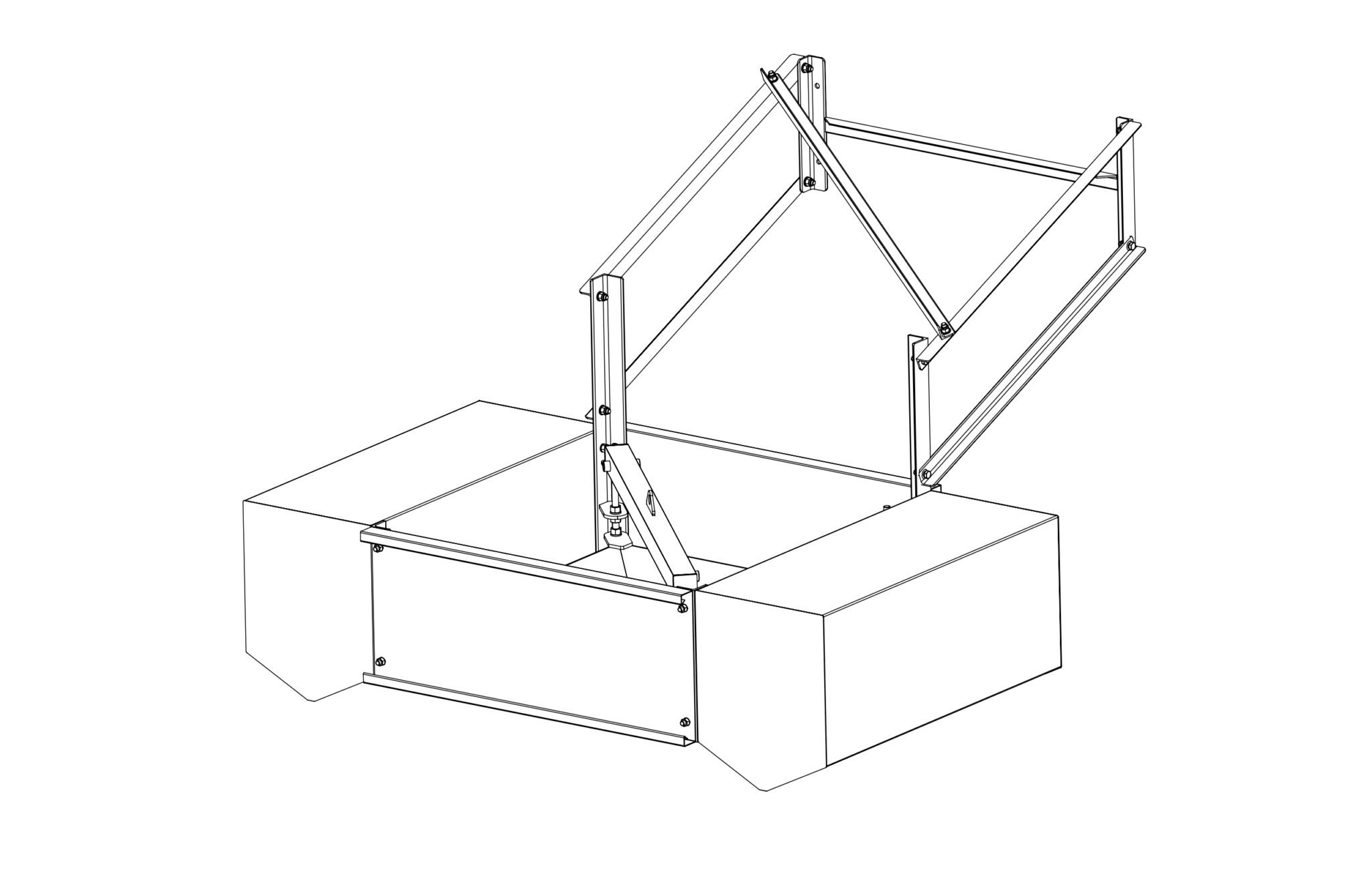

The DP type pneumatic decanter consists of a drain trough and floats. Wastewater from the clarified surface layer is collected using a drainage trough. The trough is stationary in relation to the floats that raise it on the surface of the tank. The mutual position of the trough and floats is set using adjustment screws. The connection flange allows the trough to be equipped with any drain fitting: a stub, an elbow or a submersible pump, to which a flexible drain hose is connected. The role of the deflector is played by floats and side screens of the floats that tightly surround the drain trough. The deflector is designed to prevent the outflow of pollutants floating on the sewage surface.

The sewage outflow is controlled by changing the immersion depth of the floats, which are filled with an appropriate amount of air, causing them to rise or fall. The pneumatic system does not have any moving parts, which makes it extremely resistant to failure and wear.

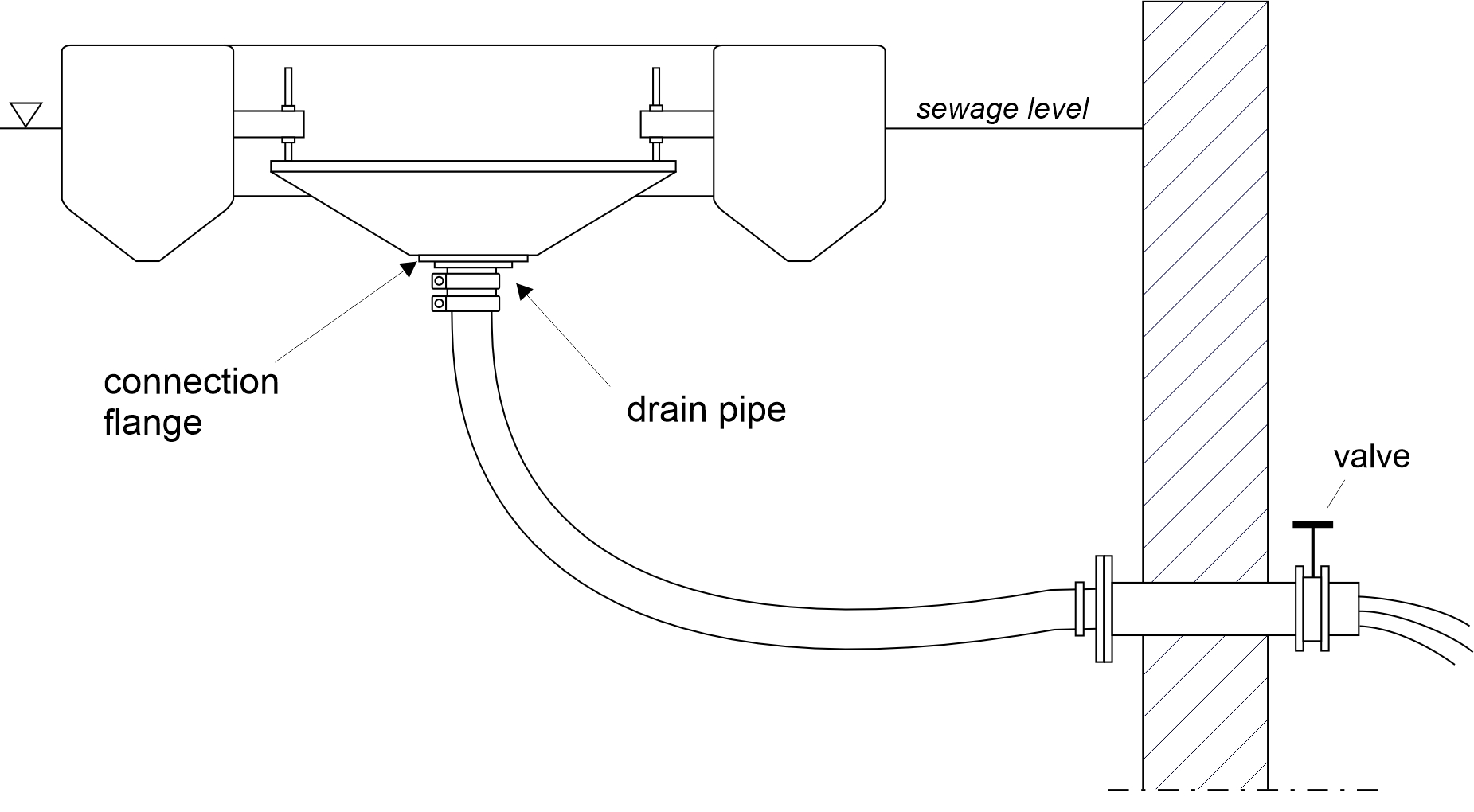

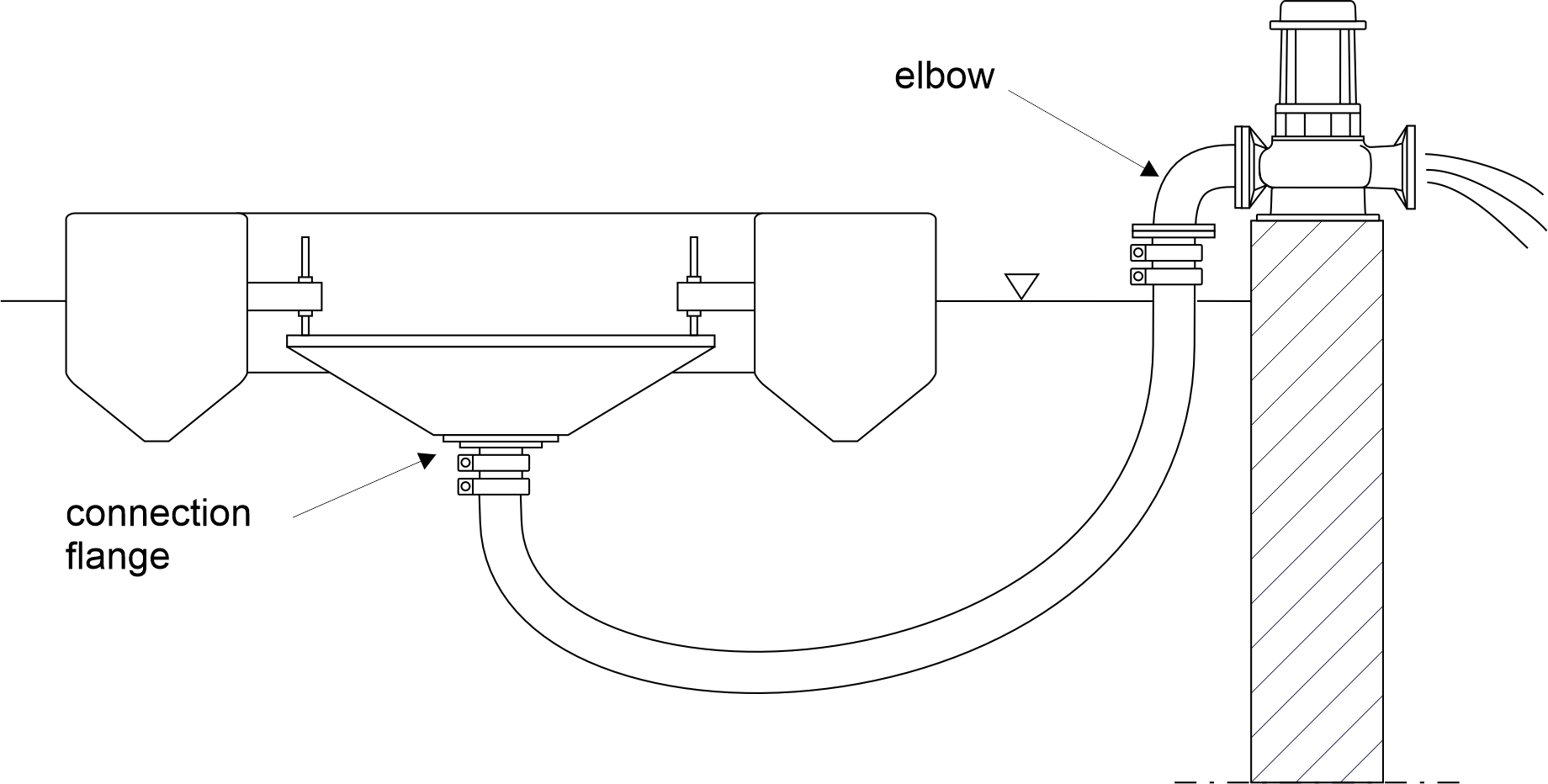

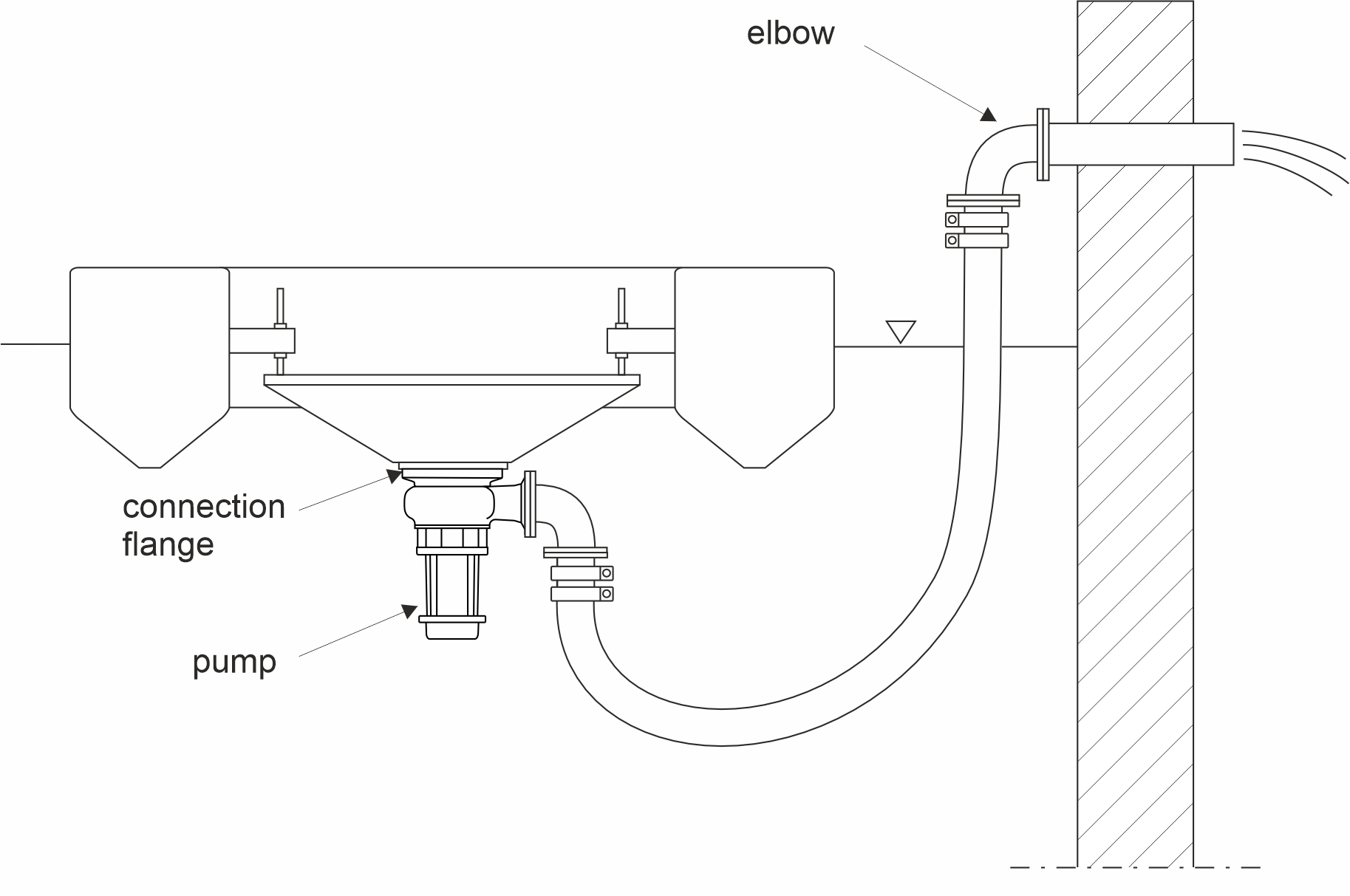

The clarified surface layer of sewage is collected by the drain trough and discharged through a flexible hose, usually attached to the drain stub of the decanter trough. Depending on the needs and conditions of a specific facility, drainage can be implemented in various ways.

Gravity drain – gravity drain can be implemented using the difference in the levels of the inlet and outlet of sewage in the drain hose. In the case of a gravity drain, a gate valve should be used at the outlet port. The gate valve allows you to control the capacity and tightly close the outlet after draining.

Pump drain – if gravity drain is not possible, the sewage discharge line can be connected to an external pump. The pump should be capable of self-priming if it is above the operating sewage level.

Pump drain using a submersible pump – sewage can also be collected using a submersible pump, attached to the connection disc of the suction collector instead of the drain stub.

Actual efficiency should be determined for specific operating conditions and depends primarily on:

– size and settings of the decanter,

– diameter, length and type of drain pipe,

– difference in sewage inlet (intake) and outlet levels,

– local losses in the pipeline (including losses at elbows – for a rigid drain pipe).

We will help you if you need to perform appropriate performance calculations.

For safe operation and trouble-free operation of the decanter, always use a gate valve at the outlet of the drain pipe.

Pneumatic decanters can be equipped with 2 stabilization systems:

Articulated stabilizer – to maintain the horizontal position of the device, it should be equipped with a stabilization system. Due to the simplicity of installation, reliability of operation in winter conditions and very high flexibility in selecting the length of elements, it is a very good and universal solution. When using an articulated stabilizer, the device is not limited to working directly at the installation site.

Roller stabilizer – in cases where there are large fluctuations in the sewage level or the size of the tank is limited, roller guides can be used for stabilization. The rollers are mounted using the same holes in the angle brackets of the float connectors as in the case of mounting the joints.